MCCB vs ACB: How to Choose the Right Circuit Breaker for Industrial and Commercial Applications

⚡ Circuit breakers are key to protecting modern electrical systems, but how do you choose between MCCB and ACB? The wrong selection can lead to system inefficiency, costly downtime, and compliance risks. This guide helps you confidently select the best option for your project—whether for a commercial building, industrial plant, or smart grid.

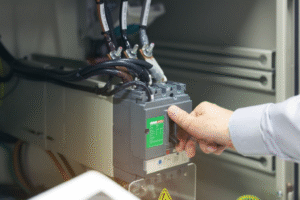

What Is a Molded Case Circuit Breaker (MCCB)?

A Molded Case Circuit Breaker (MCCB) is a compact, low-voltage device designed to protect electrical circuits from overloads and short circuits, typically rated from 10A up to 1600A. Its molded insulation case enhances durability against dust, humidity, and mechanical damage.

Key Features

- Molded Insulation Case: Shields internal components.

- Trip Unit: Combines thermal (overload) and magnetic (short circuit) trip functions.

- Arc Chamber: Effectively extinguishes arcs.

- Compact Design: Saves space and reduces installation time.

How It Works

- During overloads, thermal bimetal elements heat and bend, triggering a trip.

- In short circuit events, magnetic coils respond instantly to disconnect the circuit.

Applications

- Commercial power panels

- HVAC systems

- Motor control centers

- Distribution boxes

What Is an Air Circuit Breaker (ACB)?

An Air Circuit Breaker (ACB) is a high-capacity, programmable circuit breaker rated for 800A to 6300A, commonly used in main distribution systems and critical infrastructure. It employs air to extinguish electrical arcs during interruptions.

Key Features

- Electronic Trip Unit: Programmable settings for fault detection and protection.

- Arc Chute System: Efficient arc quenching and phase separation.

- Spring/Motor Operation: Enables fast and reliable switching.

- Smart Monitoring: Supports remote monitoring, control, and seamless IoT integration.

How It Works

- The electronic unit monitors circuit conditions and initiates contact separation during faults.

- Arcs are guided into the arc chute, where they cool and extinguish.

Applications

- Hospitals, data centers, and commercial complexes

- Industrial plants and manufacturing lines

- Smart grids, substations, and power plants

- Renewable energy systems

MCCB vs ACB: Key Differences

| Feature | MCCB | ACB |

|---|---|---|

| Current Range | 10A – 1600A | 800A – 6300A |

| Arc Interruption | Molded case + arc chamber | Air + arc chute |

| Trip Unit | Thermal-magnetic | Electronic, programmable |

| Reset Capability | Limited; depending on trip severity, some types are manually resettable | Fully resettable; serviceable |

| Footprint | Compact, panel-mounted | Larger, suitable for main switchboards |

| Monitoring | Minimal | Full remote control & real-time diagnostics |

| Applications | Branch circuits, motors, HVAC | Main panels, industrial and critical systems |

| Initial Cost | Lower | Higher initial cost, lower lifetime O&M costs |

Choosing the Right Breaker for Your Needs

Choose MCCB if:

- Your system current is up to 1600A, typically below 800A for branch circuits

- You need a cost-effective and compact solution

- Maintenance-free design is preferred

- Application involves downstream or non-critical circuits

Choose ACB if:

- System current exceeds 800A, typically used for main power distribution

- You require remote control, advanced diagnostics, or programmable delays

- Downtime must be minimized in mission-critical applications

- Installation is in smart infrastructure or high-capacity industrial systems

Why SSPD?

As a professional MCCB and ACB manufacturer, SSPD provides:

- Certified products meeting IEC/CB/CE standards

- Short lead times and global OEM support

- Smart ACBs ready for IoT integration

- 20+ years of experience in industrial power protection

🔍 Need technical guidance for your project? Contact our engineering team for a free consultation.

Conclusion

Both MCCBs and ACBs are indispensable in modern power systems. The right choice depends on:

- Required current capacity

- Desired monitoring and control features

- Maintenance strategy

- Space availability

Whether you’re designing new systems or upgrading existing ones, selecting the appropriate breaker ensures safety, efficiency, and long-term reliability. The right choice will also help reduce long-term maintenance costs and improve system uptime.

🔧 Ready to enhance your electrical systems? Request a quote or sample from SSPD today.