In modern electrical distribution and automation systems, the design of control cabinets plays a decisive role in safety, reliability, and efficiency. As key components for control and protection, AC contactors depend not only on product quality but also on how they are arranged, cooled, and integrated within the cabinet.

This article provides a practical optimization guide for AC contactor layout in electrical control cabinets, helping you reduce overheating risks, extend component lifespan, and improve system stability.

1. Component Placement & Airflow

1.1 Separate AC and DC Sections

One of the most important design rules is to physically separate AC and DC components. By using partitions or dedicated sections, electromagnetic interference can be minimized, preventing high-voltage switching from disturbing low-voltage control signals. This improves reliability and makes troubleshooting easier.

1.2 Prioritize Heat-Generating Components

Devices such as variable frequency drives (VFDs), power supplies, and relays generate considerable heat. They should be positioned close to heat sinks, fans, or natural convection channels to reduce local hot spots, protecting AC contactors and surrounding equipment from thermal stress.

1.3 Ensure Proper Airflow

Efficient ventilation is essential for contactor performance. Layout design should direct cool air over high-load, heat-sensitive components. Vertical airflow—cool air entering from the bottom and hot air exiting from the top—follows natural convection principles and enhances cooling efficiency.

2. Electrical Considerations for Contactor Placement

2.1 Voltage and Current Ratings

Select AC contactors with voltage and current ratings higher than system requirements. This ensures they can withstand inrush currents during motor or equipment startup, preventing premature wear or contact damage.

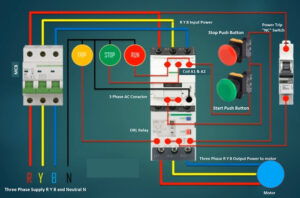

2.2 Load Type and Pole Selection

For three-phase systems, 3-pole contactors are standard, while 4-pole contactors may be required when neutral lines or special loads are involved. Correct pole selection ensures safety, simplifies wiring, and reduces installation errors.

3. General Control Cabinet Design Practices

3.1 Clear Labeling

Use durable, visible labeling for both wiring and components. This enables technicians to quickly identify circuits, reducing downtime during inspections and repairs.

3.2 Cable Management

Neat wiring improves not only aesthetics but also air circulation and safety. Apply cable ducts, ties, and harnessing methods to keep wires organized, insulated, and separated according to voltage levels.

3.3 Accessibility and Maintenance

When arranging contactors, consider future maintenance needs. Ensure adequate front-panel access and door swing space, and place frequently serviced components in easily accessible positions.

4. Benefits of Optimized Contactor Layout

Adopting these strategies brings measurable benefits:

Longer Component Lifespan – Reduced thermal stress lowers failure rates.

Enhanced Safety – AC/DC separation reduces interference and short-circuit risks.

Higher Energy Efficiency – Proper airflow minimizes excess cooling demands.

Simplified Maintenance – Organized layouts save time and reduce downtime.

5. Conclusion

Optimizing the layout of AC contactors in electrical control cabinets is more than an engineering detail—it is a long-term investment in safety, reliability, and efficiency. With careful AC/DC separation, effective heat management, correct rating selection, and structured wiring, businesses can achieve greater system stability and lower operating costs.

At SSPD (Shendian Electric), we are committed to providing high-quality AC contactors and complete low-voltage solutions. Our products comply with IEC, CE international standards, and are designed to integrate seamlessly into modern cabinet layouts. Whether you are building new systems or upgrading existing ones, our engineering team offers professional support to ensure your electrical infrastructure is safer, smarter, and future-ready.

Engagement & Transparency Statement

👉 Have you experienced issues like overheating or premature contactor failure in your projects? Share your story in the comments—we’d love to discuss solutions with you.

💡 Transparency Notice: This article was partially AI-assisted and refined with our engineering expertise and industry standards. We believe openly disclosing AI involvement builds reader trust and aligns with Google’s latest content quality and transparency guidelines.